Engineered wood is composed of layers, called “plies”. Hardwood and plywood are bonded together through a heating and pressing process. The layer you see is a veneer of hardwood that is 1/16” to 1/8” thick. The layer under that is a core of plywood. Each added ply will lay perpendicular to the one above it to provide strength and stability. The other thing it does is help prevent expansion and contraction. Engineered flooring will have at least three plies and can have as many as 12, with most having five layers. More layers means better quality flooring.

What Does Engineered Flooring Look Like?

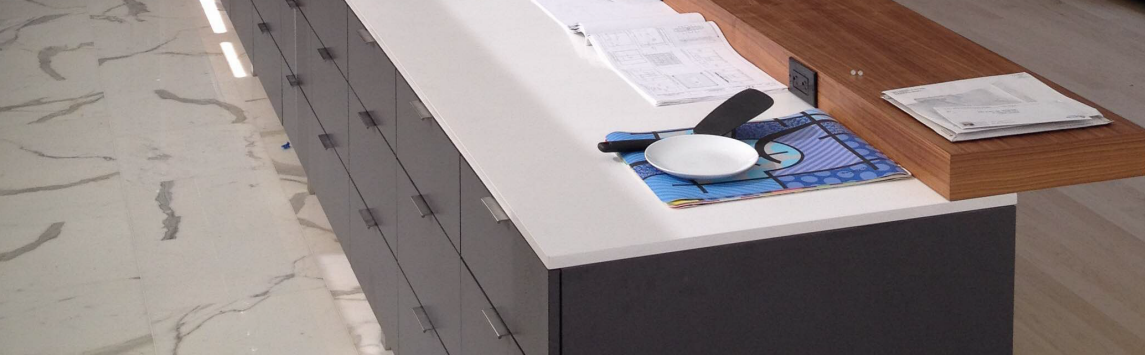

The veneer top makes it very hard to tell the difference between solid wood and engineered flooring and the wood flooring industry considers the two to be interchangeable. You would know for sure if you would see the side of it before it’s been installed because you would see the plies.

Where to Use Engineered Wood Flooring in Your Home

Engineered flooring holds up in areas that get light moisture, like kitchens, bathrooms, basements, and on top of concrete flooring. It is not going to do so well in high moisture areas that may flood. If engineered flooring is placed over concrete, the moisture content in the concrete slab cannot exceed four percent. The floor should be tested before flooring is installed over it. It’s also recommended that a vapor barrier underlayer be placed over it before installation if you have moisture concerns.

Engineered Hardwood Floor Finish Life Expectancy

How long engineered flooring lasts depends on the thickness of the plank. Thinner types can last 20 to 30 years, thicker ones can last for 40 to 80 years. These estimated lifespans may hold true if you install high-quality flooring. Cheaper flooring may not last as long as expected. How can you tell the difference between high-quality flooring and those that are cheaply made? One way for a consumer to get an idea is the price point, but the number of layers is the best way. The more layers, the better. Do not pick engineered flooring that has less than five layers. There are many species of engineered flooring that are all prefinished with seven to 10 coats of aluminum oxide, making it stronger than most applied finishes. The planks range in width from 3/8″ to 3/4″. Thinner options are at 3/8” and are nailed to the floor for stability. Thicker types of ½” can be nailed to the wood subfloor or glued to dry concrete slabs. The thickest types of 5/8” and up can be used as a floating floor. Engineered flooring can get scratched and dinged with the thickness of the veneer impacting how many times it can be sanded.

Hardwood Flooring Installation & More in Charles Town & Eastern Panhandle of Berkeley & Jefferson Counties in WV | Winchester & Frederick County | Round Hill & Loudoun County | Berryville & Clarke County | Herndon & Fairfax County VA

The verdict. If circumstances are ideal, an engineered floor can give you the best qualities of solid wood in areas of your home where you would rather not install wood. Engineered flooring is a good option for basements or over concrete, solid wood is the more durable, long-lasting option that historically, is a better option for any household space. Are you still undecided? Contact Mike’s Custom Flooring for a consultation today!